PRODUCTS CENTER

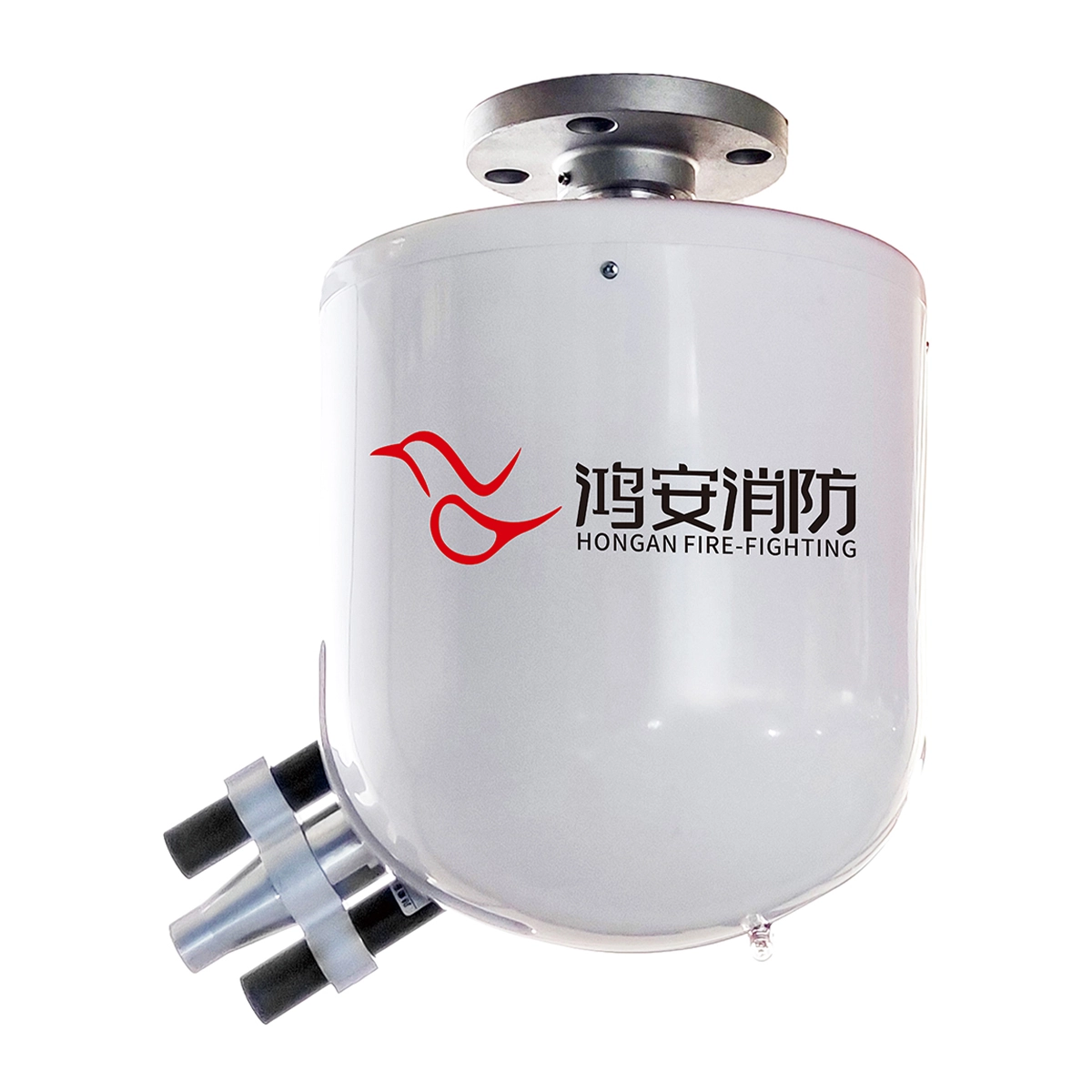

The automatic tracking and positioning jet fire extinguishing device is based on infrared and ultraviolet sensing technology and automatic control technology. It can automatically detect, lock onto, and extinguish the fire source, extinguishing the fire in its infancy. It can be used in large indoor spaces such as shopping malls, workshops, and warehouses.

The automatic tracking and positioning jet fire extinguishing device is based on infrared and ultraviolet sensing technology and automatic control technology. It can automatically detect, lock onto, and extinguish the fire source, extinguishing the fire in its infancy. It can be used in large indoor spaces such as shopping malls, workshops, and warehouses.

This series of fire extinguishing equipment integrates computer technology, optical detection technology, mechatronics technology, and video image transmission technology. Targeting the large amount of red and infrared radiation released by combustibles during combustion, it uses an electronic component (1) sensitive to this type of red and infrared radiation to perform non-contact, long-distance, multi-band, omnidirectional, active reception detection of fire, and converts it into an electrical signal. Then, through an automated control circuit, it drives the horizontal and vertical rotation mechanisms of the fire cannon to quickly and accurately aim the nozzle at the fire source. Subsequently, it automatically starts the pump and opens the valve, accurately spraying the extinguishing agent towards the target, instantly extinguishing the newly ignited fire.

This series of fire extinguishing equipment integrates computer technology, optical detection technology, mechatronics technology, and video image transmission technology. Targeting the large amount of red and infrared radiation released by combustibles during combustion, it uses an electronic component (1) sensitive to this type of red and infrared radiation to perform non-contact, long-distance, multi-band, omnidirectional, active reception detection of fire, and converts it into an electrical signal. Then, through an automated control circuit, it drives the horizontal and vertical rotation mechanisms of the fire cannon to quickly and accurately aim the nozzle at the fire source. Subsequently, it automatically starts the pump and opens the valve, accurately spraying the extinguishing agent towards the target, instantly extinguishing the newly ignited fire.

The explosion-proof image-type automatic fire cannon system consists of an image locator, an explosion-proof fire cannon, an explosion-proof control panel, an explosion-proof red-infrared detector, and a host computer. The system effectively combines image security monitoring, fire detection, and image positioning systems to provide all-weather automatic monitoring of the protected area. In the event of a fire, the system will immediately initiate an intelligent scan of the area to locate the fire source and determine its coordinates. After intelligent identification by the central controller, a fire alarm signal is issued, and the water pump is started, valves are opened, and the fire extinguishing device aims at the fire source to extinguish it. If new fire sources appear, the fire extinguishing device will repeat the process until all fire sources within the protected area are extinguished, after which the system returns to the monitoring state. The system uses explosion-proof design and meets relevant national standards, suitable for high-risk locations such as industrial and mining enterprises, petroleum, and chemical plants.

Explosion-proof electric control fire cannons are mainly composed of explosion-proof fire extinguishing devices, explosion-proof field control panels, explosion-proof wireless remote controllers, etc. They can remotely control the horizontal and vertical rotation of the fire cannon, accurately controlling the water jet. The water jet can be a water column or water mist to meet different fire extinguishing needs. The system adopts an explosion-proof structural design that meets national standards. It is suitable for heavy fire trucks, fireboats, industrial and mining enterprises, warehouses, oil fields, fixed fire extinguishing equipment for storage tanks, etc.

The PLKAEX series fixed electric control fire foam monitor features a large flow rate and long range, enabling remote wired/wireless control and local manual control. The motor and junction box are explosion-proof, and the electrical control cabinet can be placed in the control room for remote operation and positioning, facilitating the safe evacuation of firefighters from the fire scene and ensuring safe and effective fire extinguishing. Suitable for various oil, gas, and dust hazardous explosion sites.

Hongan Fire Equipment Co., Ltd.

No. 101, Nantong Road, Ximei Street, Nan'an City, Quanzhou City, Fujian Province

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.